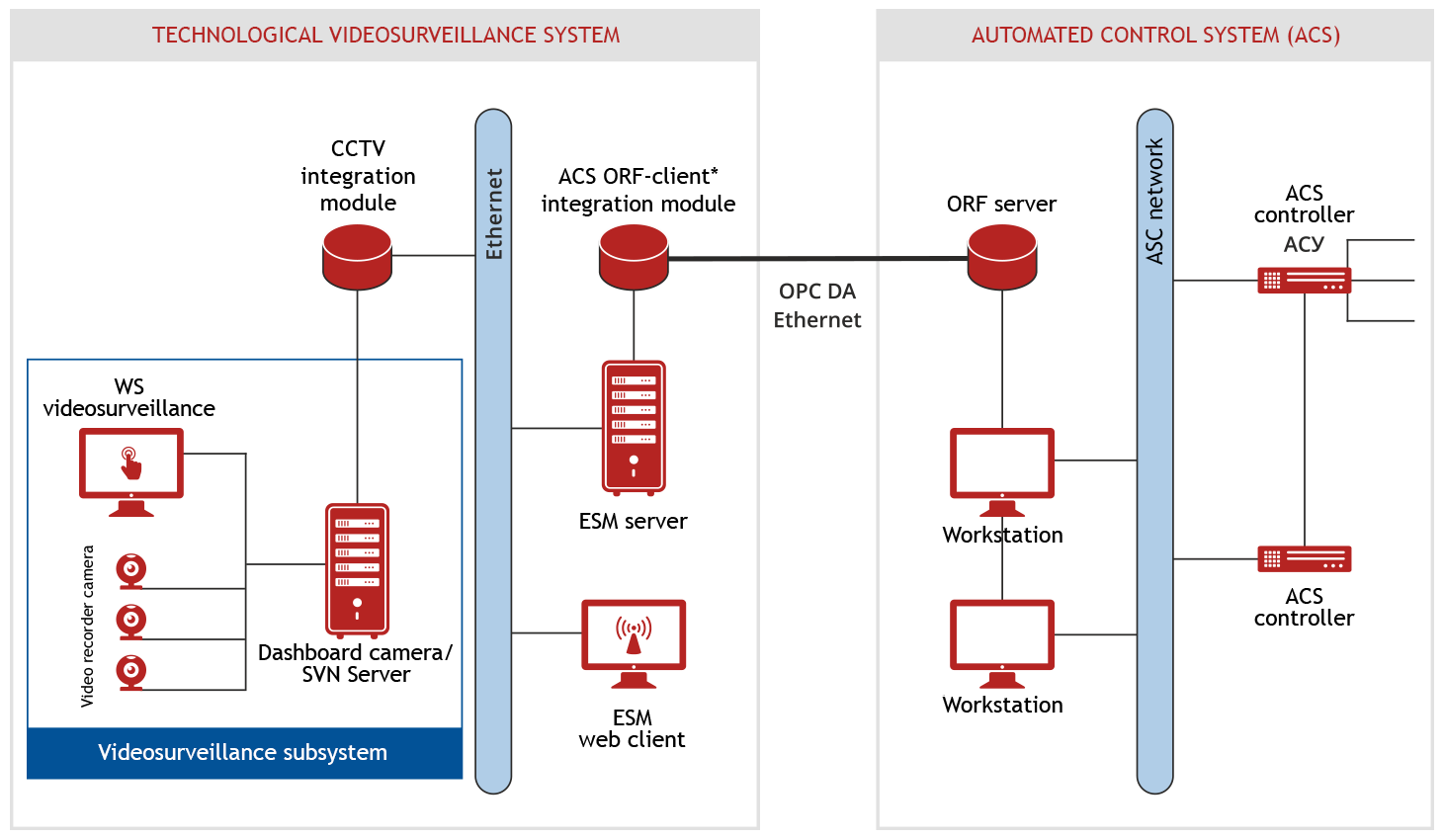

The solution is based on the integration of industrial process control system and videosurveillance systems. As a result, obligatory alarm sources from the CPCS (flow sensors, temperature sensors, thermometer-regulator, flow meters, etc.) are completed by visualization tools.

This solution is for You if it is necessary:

- To provide visual verification of the technological process.

- To provide the possibility of remote reading instrumentation data.

- To reduce impacts on operating staff.